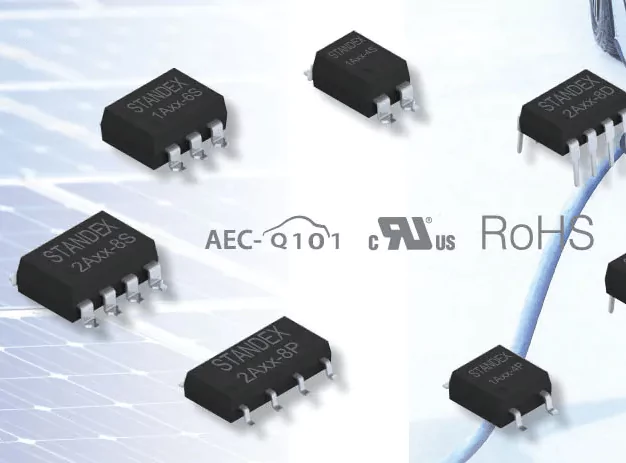

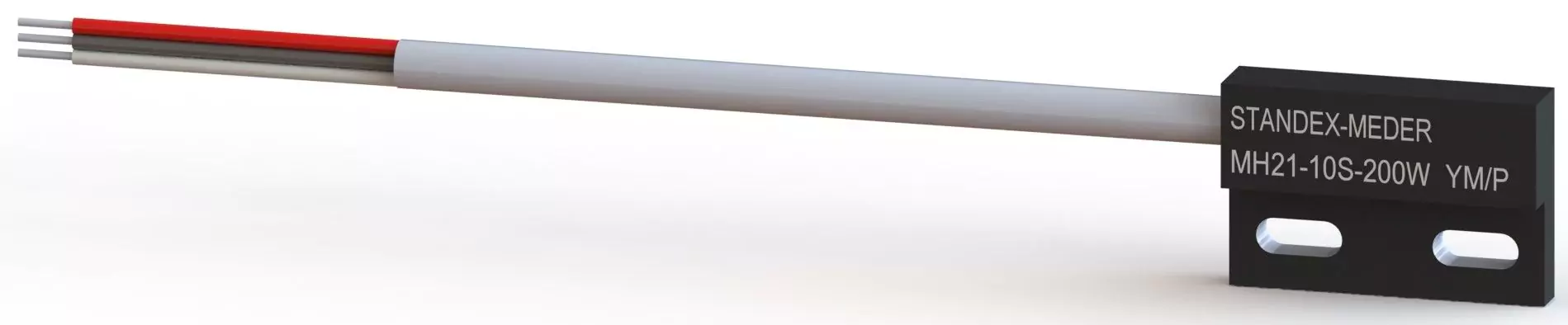

Why Standex Electronics Reed Relays and Reed Sensors?

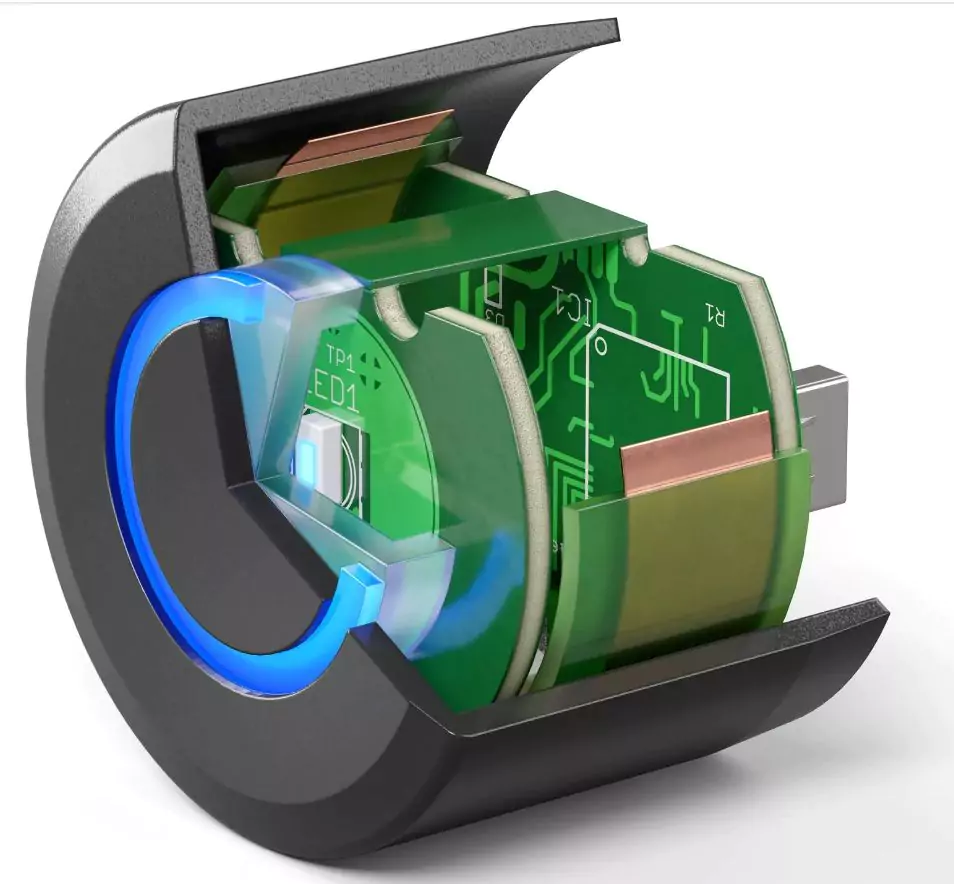

To meet the current electronic manufacturing trends surface mountable reed sensors and reed relays offer a long list of exceptional features when designed and packaged for surface mounting on printed circuit boards (PCBs). Their adaptable designs, rugged packaging, and capability of switching into the billions of operations make them an ideal design against other switching technologies.

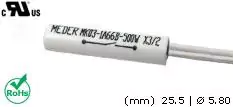

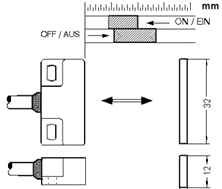

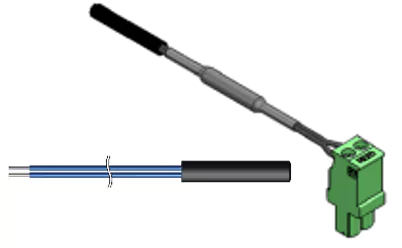

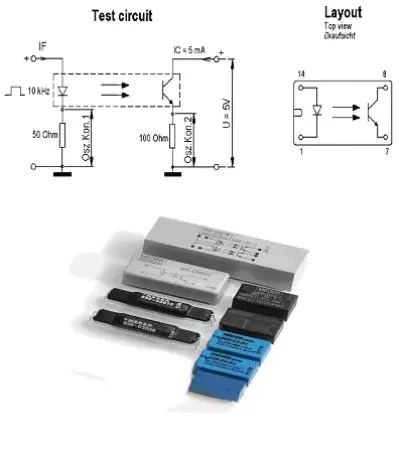

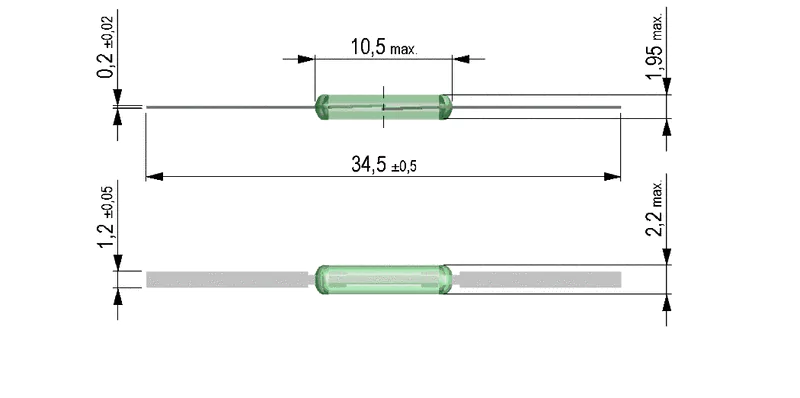

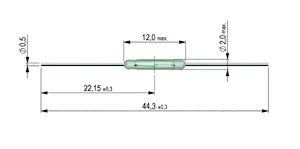

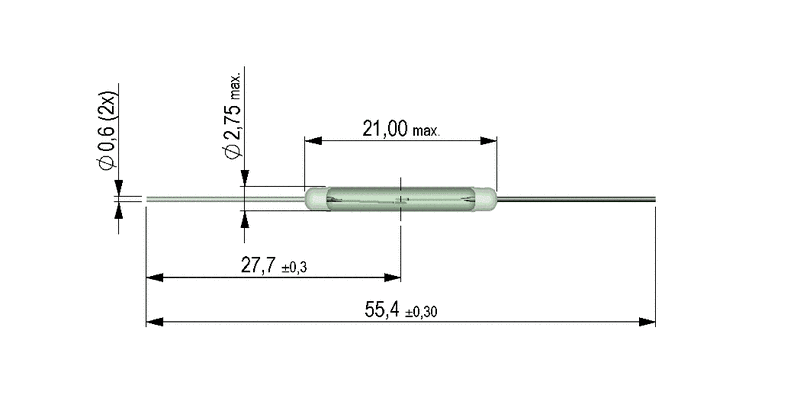

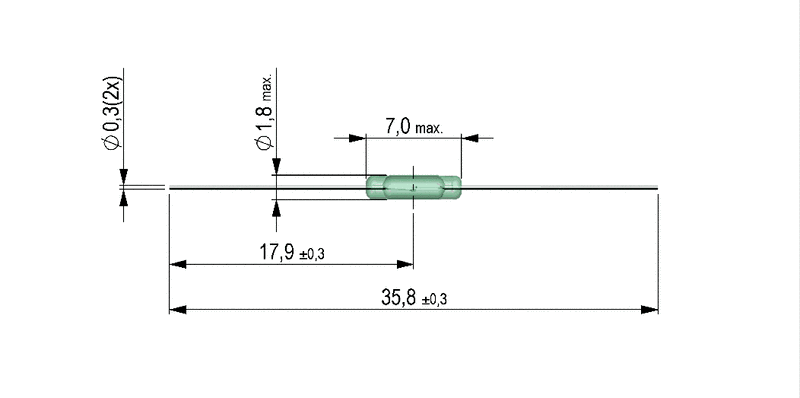

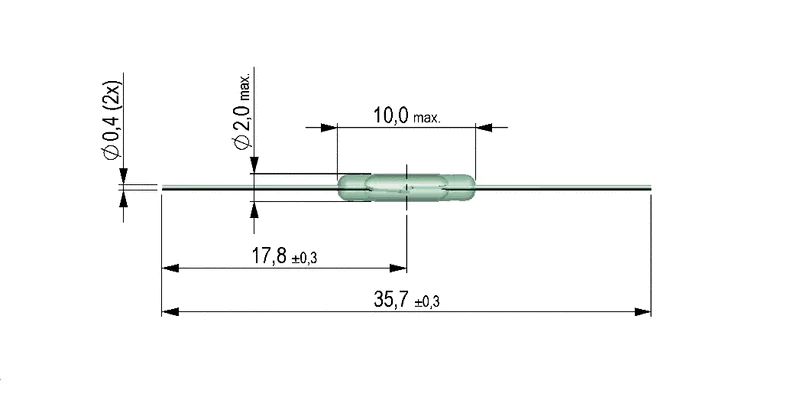

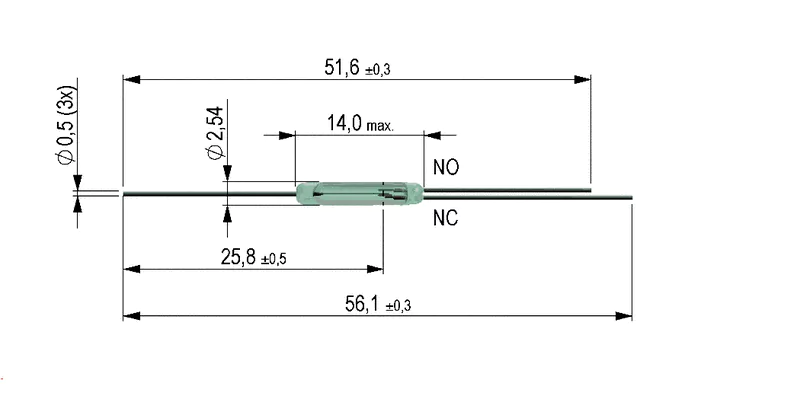

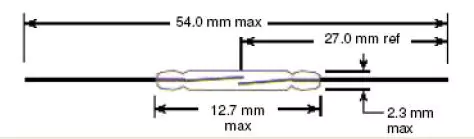

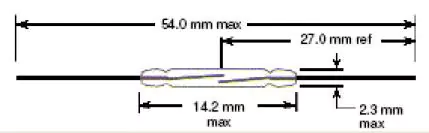

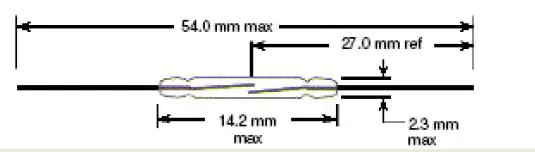

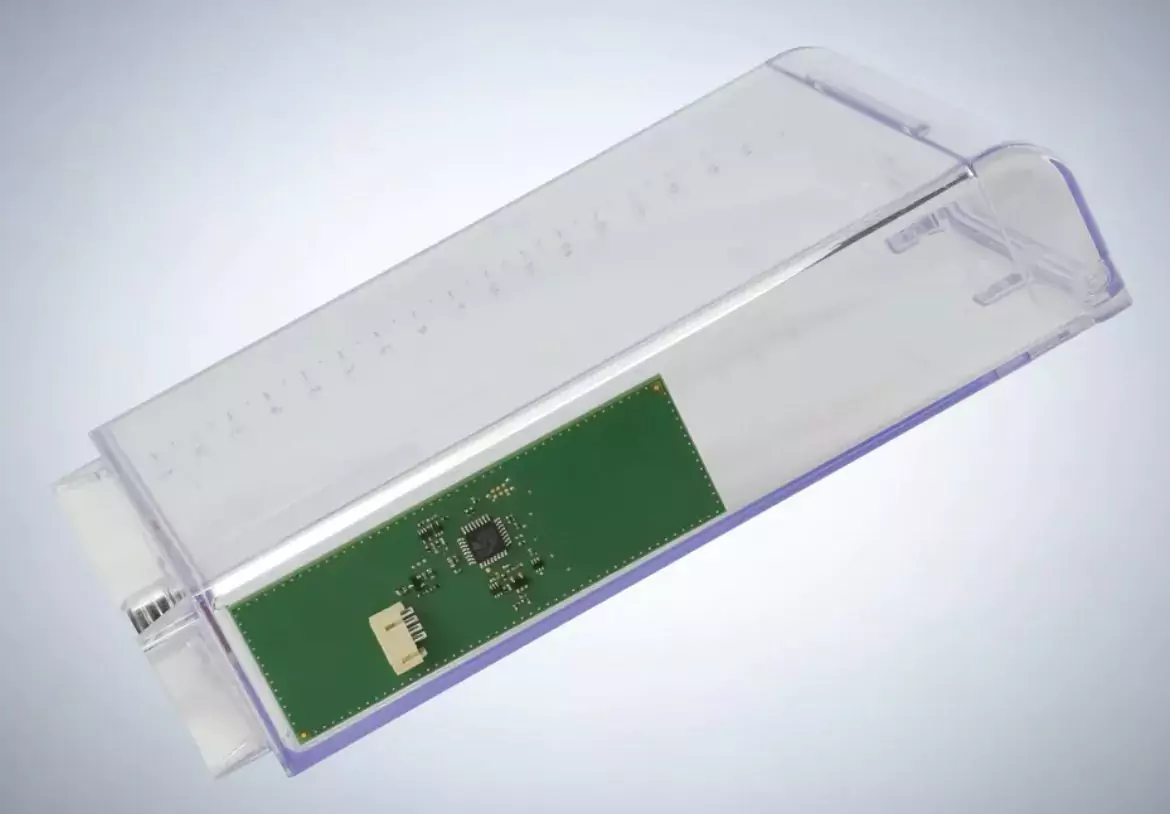

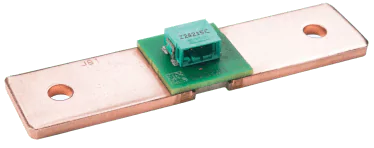

The reed sensors and reed relays are packaged in low profiles with flat leads that meet all skewing and co-planar specifications. These accurately formed leads are generally bent into ‘J’ leads, gull leads, and axial leads, where gull leads are the most popular. “J” leads are utilized to minimize PCB space. Axial leads can be used to lower the component profile where a hole is cut or punched in the PCB allowing almost half of the sensor or relay to reside below the surface of the PCB. In this case, their RF characteristics are maximized as well. The reed sensors and relays with all the above lead configurations are generally packaged in ‘tape and reel’ for ease of customer manufacturability.

These rugged sensor and relay designs all use our hermetically sealed reed switches and packaging that takes their coefficient of thermal expansion (CTE) into consideration, where they are all closely matched to each other. This is a critical aspect of the design since the reed relays/sensors are typically subject to an infrared soldering process where they are immersed in oven temperatures as high as 300°C (572°F) for up to 3 to 4 minutes. The closely matched CTEs avoid any potential internal stress at the high ambients.

Standex Electronics designs are generally smaller than thru-hole designs and offer excellent quality and reliability. Because of their smaller size, the signal path through the reed relay or sensor is shorter, because the signal does not have to travel down the thru-hole leads through a PCB, but simply stays on the PCB surface. This feature makes them ideally suited for RF applications and where switching very fast digital pulses are required.

All the features associated with Standex Electronics’s reed switch technology are captured in the SME reed sensors and reed relays:

- Stable low contact resistance

- High switching voltages

- High carry currents

- High breakdown voltages

- Build-in hysteresis

- Ultra high insulation resistance

- Dynamic contact resistance testing and more

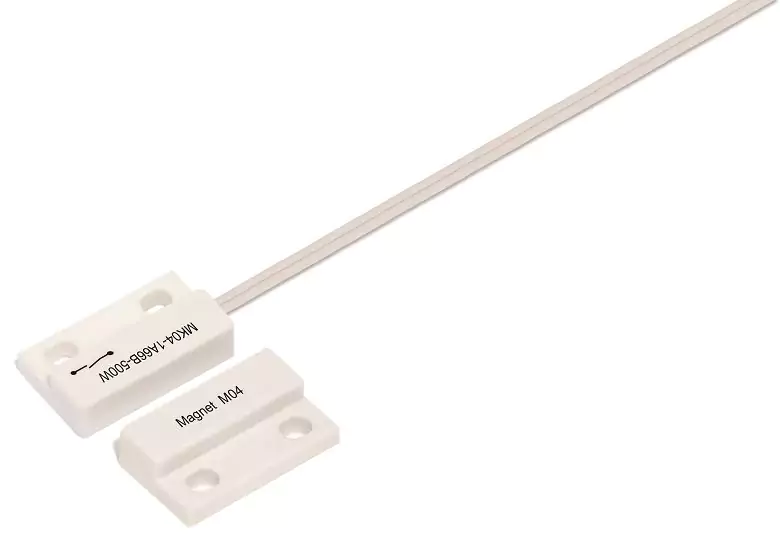

The SME reed sensors/relays open up numerous new applications not available in thru-hole technology and other mechanical switching devices. These new applications are found in:

Industry applications

Automatic test equipment (ATE), Instrumenta- tion, Automotive, Marine and Boat, Appliances Consumer electronics, Water flow sensing, Telecom, Oil well drilling, Medical, Security Industrial, and others.

Features

- Surface mountable

- Very low profile

- High quality and reliability

- Rugged thermoset over-molded packaging

- Ability to withstand high and low ambient temperatures

- Ability to meet solder reflow temperatures up to 300°C (572°F) for up to 3 to 4 minute

- Ideal for RF Characteristics

- Switch and carrying fast digital signal > 5 GHz

- Switch and carry signal level RF up to 20 GHz

- Skew rates less than 20 picoseconds

- 50Ω characteristic impedance

- Switch to shield capacitance <0.5 picofarads

- Dielectric strengths across the contacts 200 volts

- Standex Electronics reed relays and reed sensors with their hermeticity, offer better overall performance when designed for and used in a surface mounting environment. The design, size, and technical characteristics are all enhanced.