What is Q Factor?

The quality factor (Q) of a resonator is expressed as the ratio of stored versus lost energy per oscillation cycle. Overall losses through a resonator increase as Q factor drops and will increase more rapidly with frequency for lower values of resonator Q. However, truly understanding how Q factor is determined is a bit more intricate. Let’s take a closer look.

Understanding the Different Components of Q Factor

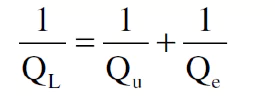

There are three types of Q – loaded Q, unloaded Q (Qu), and external Q (Qe) that make up Q factor. QL is measured by looking at a plot of a filter’s performance. The standard definition of QL is as a figure of merit (FOM) for bandwidth:

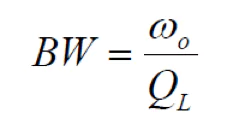

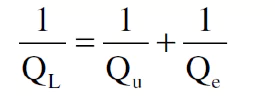

QL is driven by what goes on inside the filter, which is the Qu, and the way that the device is coupled to the external world, which is the Qe:

In general, QL is a convenient way to talk about a filter’s performance as plotted. But when it comes to what makes a filter work the way it does, it’s best to look at the unloaded Q of the resonators the filter is built up from.

Qu can vary across filter technologies. In a metal waveguide at mmWave frequencies, Qu is usually around 2,000, while an on-chip filter, such as an RFIC, will run in the range of 25 to 100. Additionally, Qu can vary broadly within a class, such as the microstrip filter, which is one of the technologies we work with. A microstrip device Qu typically ranges from 200 to over 300, depending on the implementation.

Factors Affecting Q

Our job at Knowles Precision Devices is to find the optimal approach for your application, but in general there are several factors we keep an eye on for designing a filter with the “best” Q. These include dielectric loss, metal loss, and radiated loss. First, dielectric loss is determined by the dissipation factor or loss tangent of the substrate material as well as the thickness of the substrate. The lower the loss tangent and the thicker the ceramic substrate, the higher the Q factor.

Metal loss is determined by several factors including the conductivity of the conductor material, skin depth at the operating frequency, and the surface finish of the substrate material. The higher the conductivity and smoother the substrate surface, the higher the Q factor. Regarding skin depth, it is necessary to determine the correct metal thickness per the operating frequency. It is recommended that a minimum of five skin depths be used to achieve maximum efficiency.

Additionally, in typical ceramic microstrip components, gold conductors are usually used because of the high conductivity and corrosion resistance. While copper has better conductivity than gold, it is susceptible to oxidation, so a lossy protective barrier layer needs to be applied for protection when copper is used.

Finally, radiated loss usually has the smallest effect on the Q factor. Radiated loss can occur when filters are placed near neighboring components that can unintentionally couple energy off the filter. Therefore, proper shielding is important to ensure that the filter will not negatively affect or be negatively affected by other system components. Our filters can be designed with integrated shielding to protect the component from interactions with neighboring components.

QL and Qu are useful tools for understanding how a filter does what it does, but when it comes down to it, we find customers care more about what a filter is actually capable of rather than the specific Q factor. Thus, in general, we advise that when considering filter options, it is best to not shop based on Q factor alone, but to focus more on concrete passband FOMs such as bandwidth, center frequency, insertion loss, and passband ripple.