Sensor solutions for coffee machines and fully automatic coffee machines

Coffee machines with special comfort

Whether in a private household, in a cafeteria or in a catering business: coffee machines and fully automatic coffee dispensers are in constant use and should always function reliably. Users enjoy the increasing automation. The reliable automatic detection of the respective container and supply of coffee beans, fresh water, milk and cleaning fluid or the fill level in the drip water tray is one of the features of convenient fully automatic coffee machines. With the help of capacitive buttons, intuitive control panels can be implemented for even more convenient use of the coffee machine. If desired, the coffee machine can recognise the presence, position, height, volume and fill level of the cup itself. This makes it possible to implement intelligent automated operating concepts. All these solutions are offered by the development programme of EBE sensors + motion. EBE sensors + motion develops the sensor technology for level measurement individually for each model.

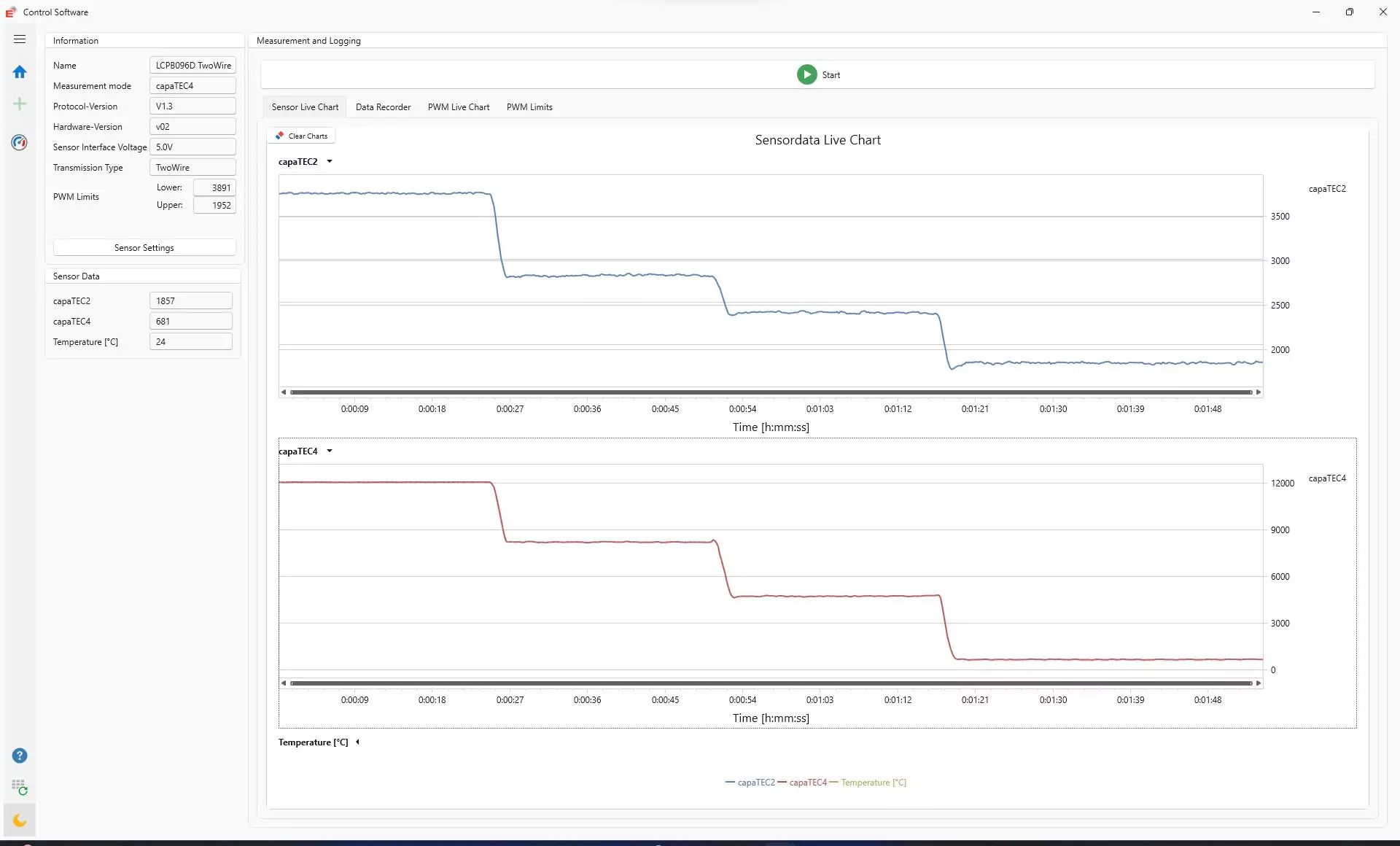

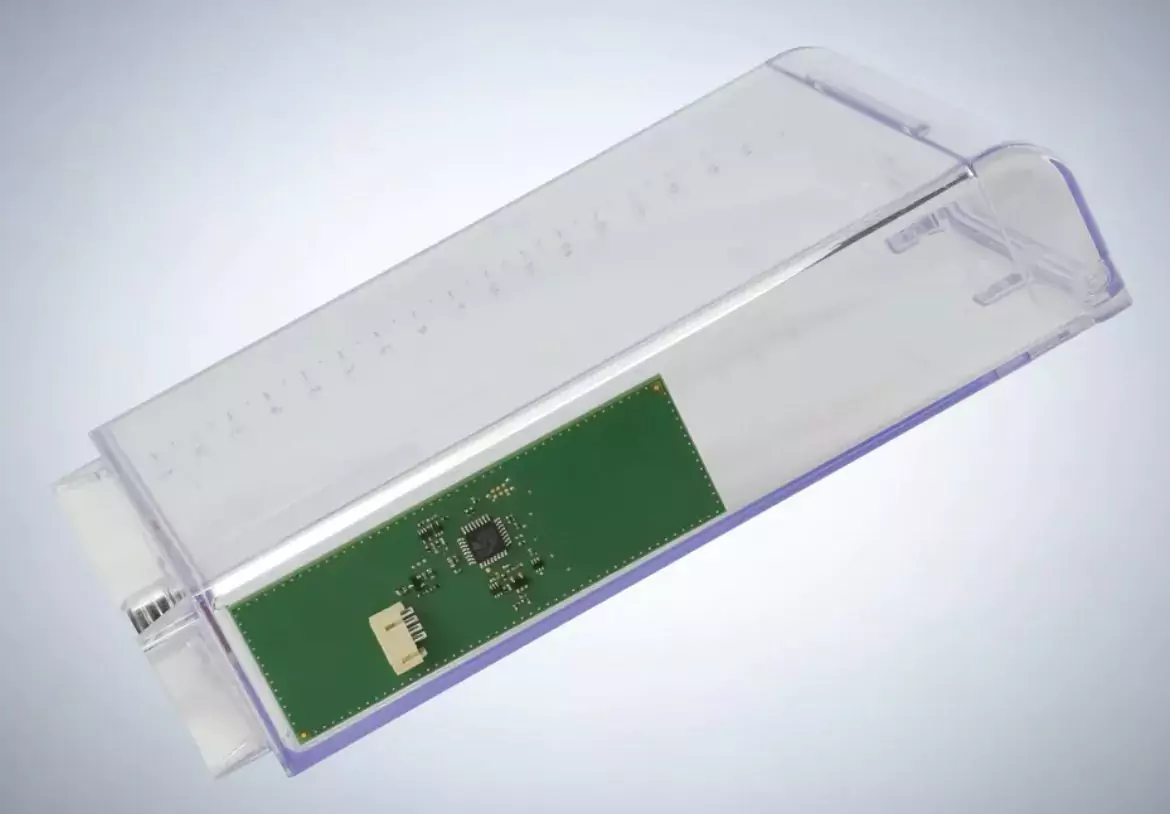

Sensor technology for level measurement

The capacitive sensor technology capaTEC® developed by EBE makes magnetic floats in fresh water tanks superfluous. This means that no float can get stuck or calcify. At the same time, the geometry of the tank can be simplified. capaTEC® level sensors can, depending on the requirement, determine the minimum level in a fresh water tank or measure the level continuously. They are also capable of detecting biofilm build-up to indicate or even eliminate the need for cleaning. The storage container for coffee beans can also be monitored by sensors from EBE. By using capaTEC® sensors, conventional resistive sensor technology can be dispensed with even in the drip water tray. Coffee residues and other dirt in the drip tray do not interfere with our level sensors in their work in any way. As the measurement takes place through the wall of the drip tray and the machine housing, the sensor has no direct contact with the medium. This guarantees a safe, error-free function of the machine.

Measurement of highly adhesive media

Highly adhesive media pose a challenge for level sensors. EBE sensors + motion also has a solution for this task. The basis of the product development is the corTEC® technology for level measurement. corTEC® sensors measure liquids with extreme adhesion and film formation in their storage tanks, e.g. milk and cleaning liquids. The film formation on the inside of the tank can be "blanked out". There are no false readings.

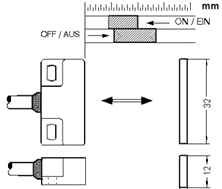

Inductive measuring principle detects tanks

With all EBE solutions for level measurement, the presence detection of a tank can be implemented. The additionally installed inductive sensor allows reliable detection and signalling of a container without additional elements. The additional sensor technology can be installed directly on a printed circuit board together with the level sensor technology. Presence detection is particularly important when hot water is pumped back into the tank in certain applications. This is often the case, for example, with professional fully automatic coffee machines. Here, it must be ensured that the tank container is actually inserted. EBE's sensor solution reliably signals here whether the tank is present and correctly inserted.

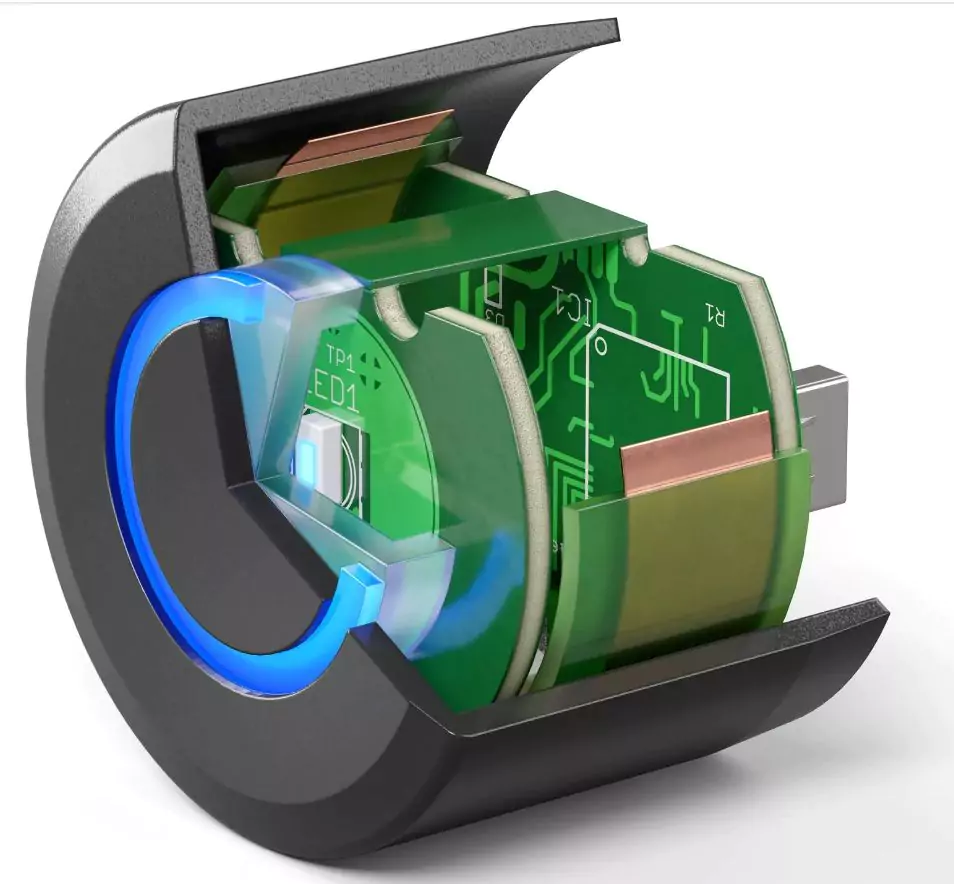

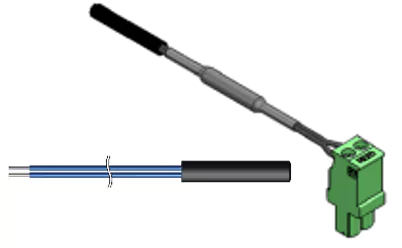

Object detection for hot beverage dispensers and fully automatic coffee dispensers

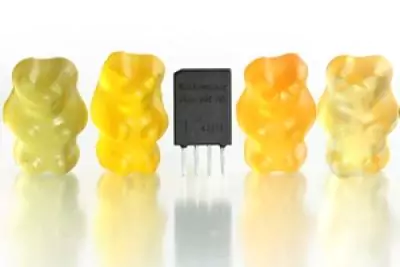

In the case of hot beverage vending machines and fully automatic coffee machines, it can be useful for the machine to recognise independently whether a container has been set and its size. Thanks to the 3D ToF sensor system used, the machine is able to check whether a selected programme also matches the container placed underneath. Before the brewing programme is started, the sensor measures the cup placed underneath for presence, correct positioning, height and capacity. This prevents overflowing and the outlet carriage can be moved to the optimum position.

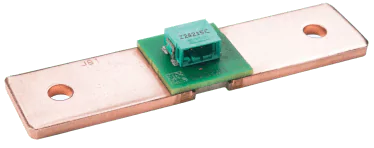

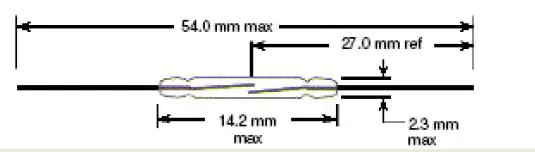

Level measurement in metal tanks

Electrically conductive or metallic tanks present a further challenge for level sensors. Such tanks are often used in professional coffee machines. Both technologies developed by EBE for level measurement can be used here. For example, they can be used in the form of a rod probe sensor for measurement in the medium.

Ask our expert for the right solution for your coffee machine development.