Power magnetic component solutions for efficient and reliable electric vehicle chargers

“The number of fast and superfast electrical car chargers is exponentially increasing. Maximum power density, excellence in thermal management, high reliability components always assuring a cost driven design are the key requirements that the market is demanding. Our solutions are helping EV charger manufacturers meet these requirements”

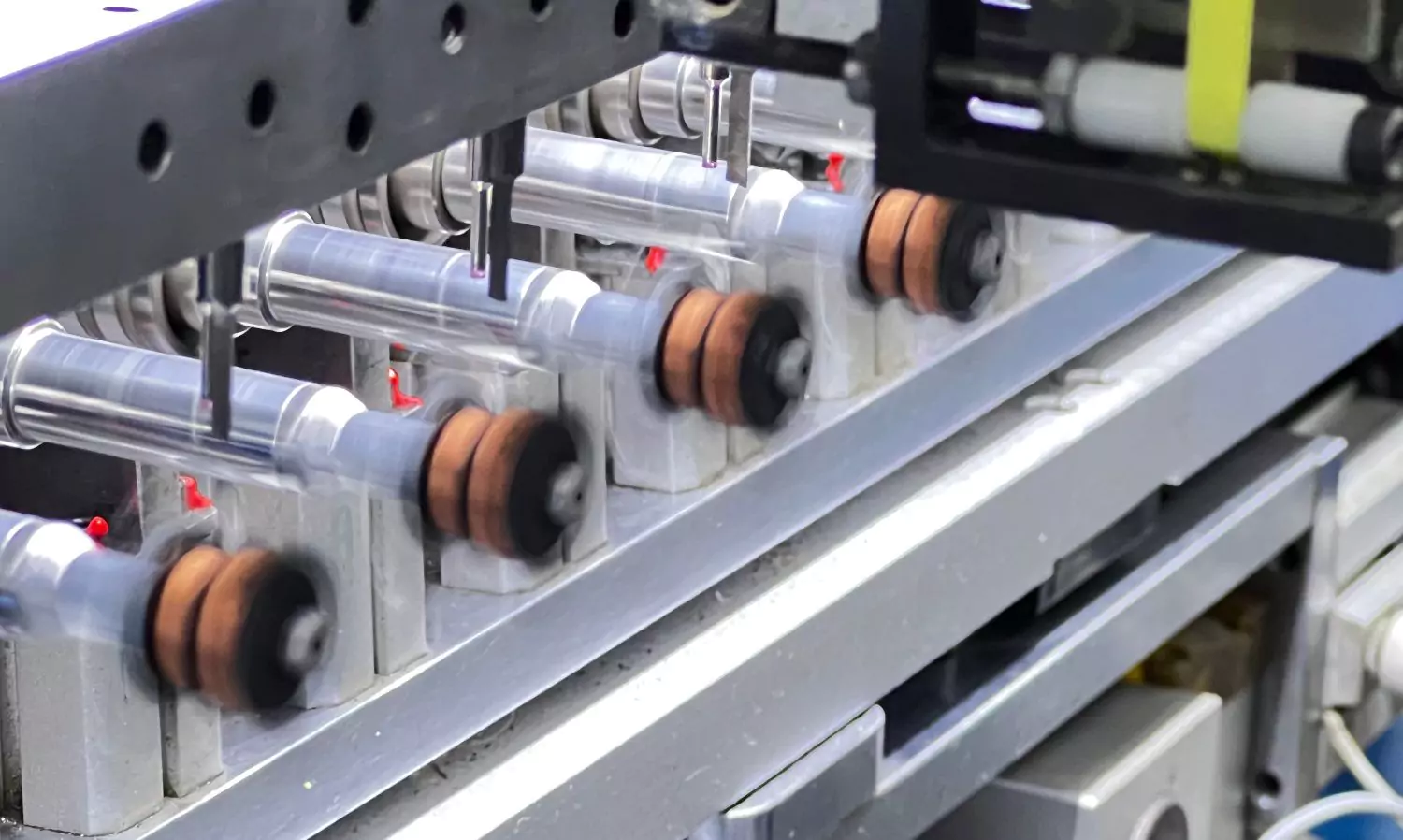

At Prax we design and manufacture inductive components for power electronics applications, creating added value through customized solutions that help our clients in the industrial and automotive sectors to create reliable and high-quality products.

Prax core competencies are magnetic components and filtering technologies combining a high level of customization possibilities with a comprehensive range of standard components. With a special focus on design support to our customers’ engineering teams, prototypes and specifications are released within a short time frame.

Global customers need global solutions. Besides our outstanding design support, PRAX strives to be a strategic partner by providing global service and support. With a multi-site manufacturing approach, PRAX offers flexible operations, allowing us to establish customized supply chains according to customer requirements.

With our long experience in design and industrialization of inductive components and EMC filters, PRAX offers services based on component specifications, cost analysis, materials selection and pre-industrialization analysis.

Our needs

- Maximum electrical performance in minimum space.

- Excellent thermal management to ensure the high quality standards of your end customer.

- A partner able to support you from the design phase to the industrialization, matching customers‘ expectations, assuring flexibility in the demand management.

Strategic needs

- Design flexibility with components that guarantee maximum adaptation to your requirements

- Know-how ownership

- Full control of the power electronics design

- Go beyond inherent limitations of usage of externally designed power modules

- Design focused on Maximum Uptime

- Reliable partner/supplier over the project lifetime

- Cost driven design

Design needs

- Maximum power density and minimum losses

- High reliability components

- Optimized layout for heat dissipation with forced air or cool plate

- Excellent thermal management

- Cutting-edge technology chargers with innovative switching topologies

- Experienced design partner in critical components including custom magnetic

What we propose

- Custom as standard: Customized solutions industrialized as standard.

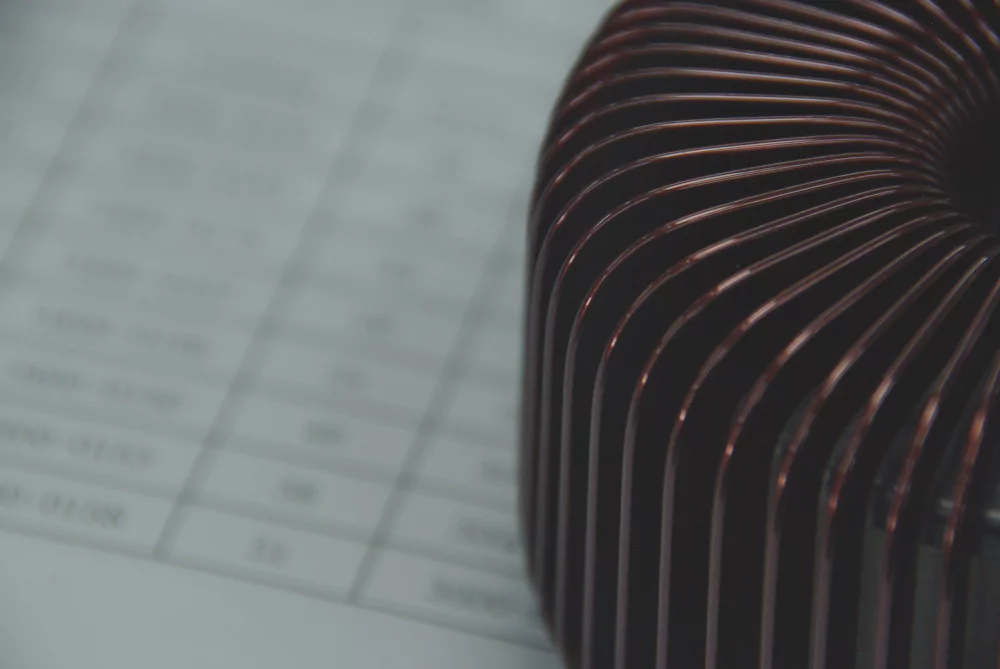

- Maximum power density, minimum losses, and excellent thermal management thanks to our innovative technology Xgap.

- Flexible, reliable and agile partner over the project lifetime with early involvement in the desing activities.

Achieving the optimal solution is possible by balancing the following keys

- Custom optimized solutions for most advanced resonant topologies

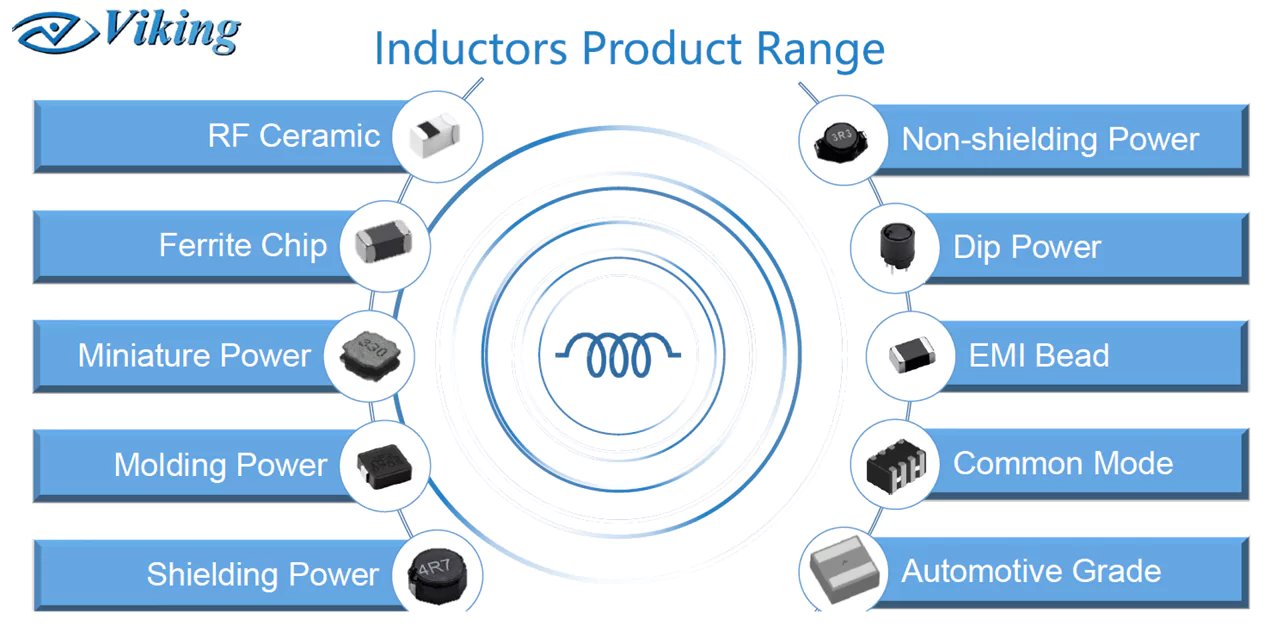

- Complete magnetic components range for EV Chargers

- Single transformer and inductor solutions up to 30kW

- Transformer + resonant inductor integrated in one component or in one assembly

- Small footprint

- Extended thermal and mechanical protection with different potting solutions

- Magnetic components designs minimizing losses

- Custom mechanical solutions

- Support since the early beginning of the project

- High performance designs with X-Gap multigap technology solutions

- Smooth transition to production with own manufacturing facilities

- Cost effective design focus

- Losses and thermal performance simulations

- Quick turn samples/prototypes IEC-61851 compliance

- IATF 16949 quality procedures

Complete magnetic component solutions for your DC chargers

As an R&D Engineer you expect

- Outstanding support during the design phase of the components

- Quick turn samples

- Advanced simulation capabilities for optimal customization and performance

As a Supplier Quality Engineer you expect

- Reliable supplier

- APQP design processes FMEA

- IATF16949

- ISO 9001

- ISO 14001

As a Commodity Manager you expect:

- Cost-effective components Flexible supply chain Reliable lead times

- Consignment stock, Kanban, JIT sourcing