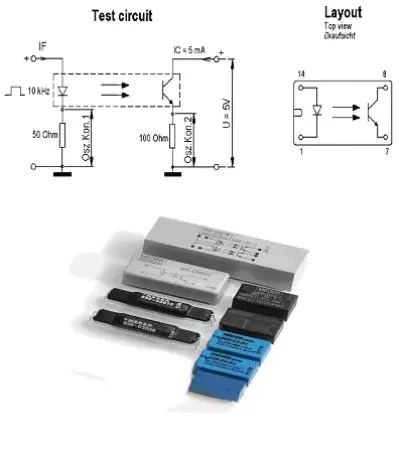

Planar transformers and inductors design guide

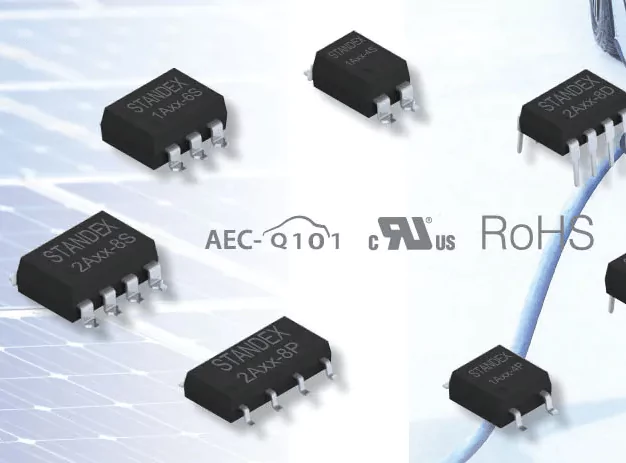

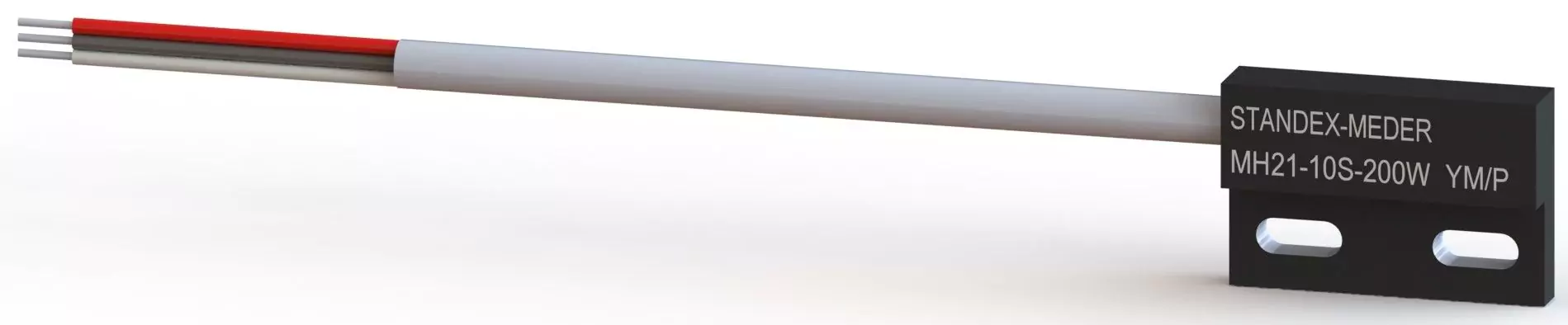

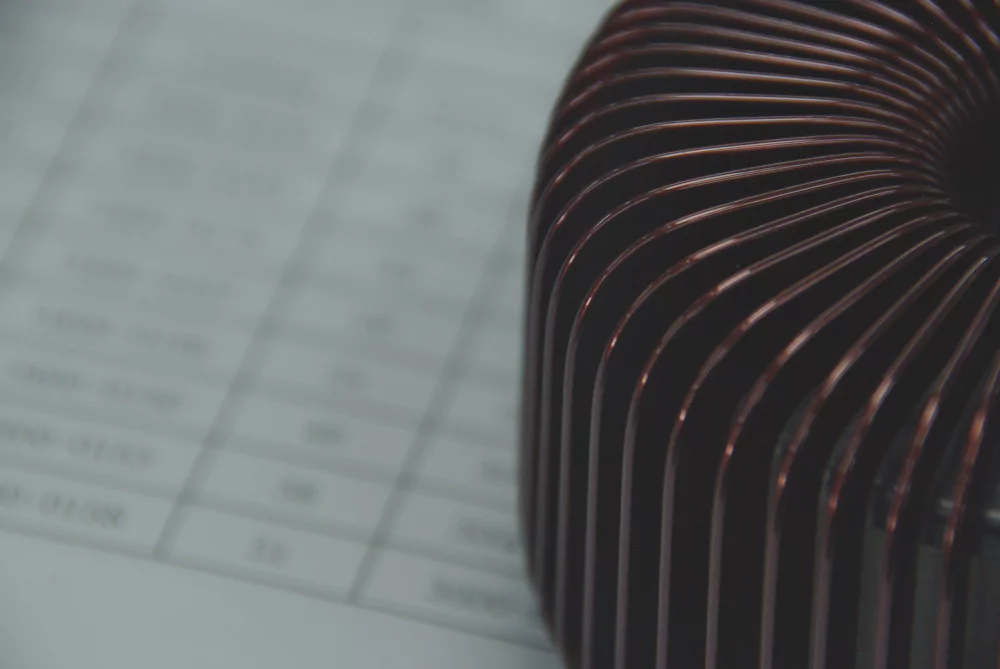

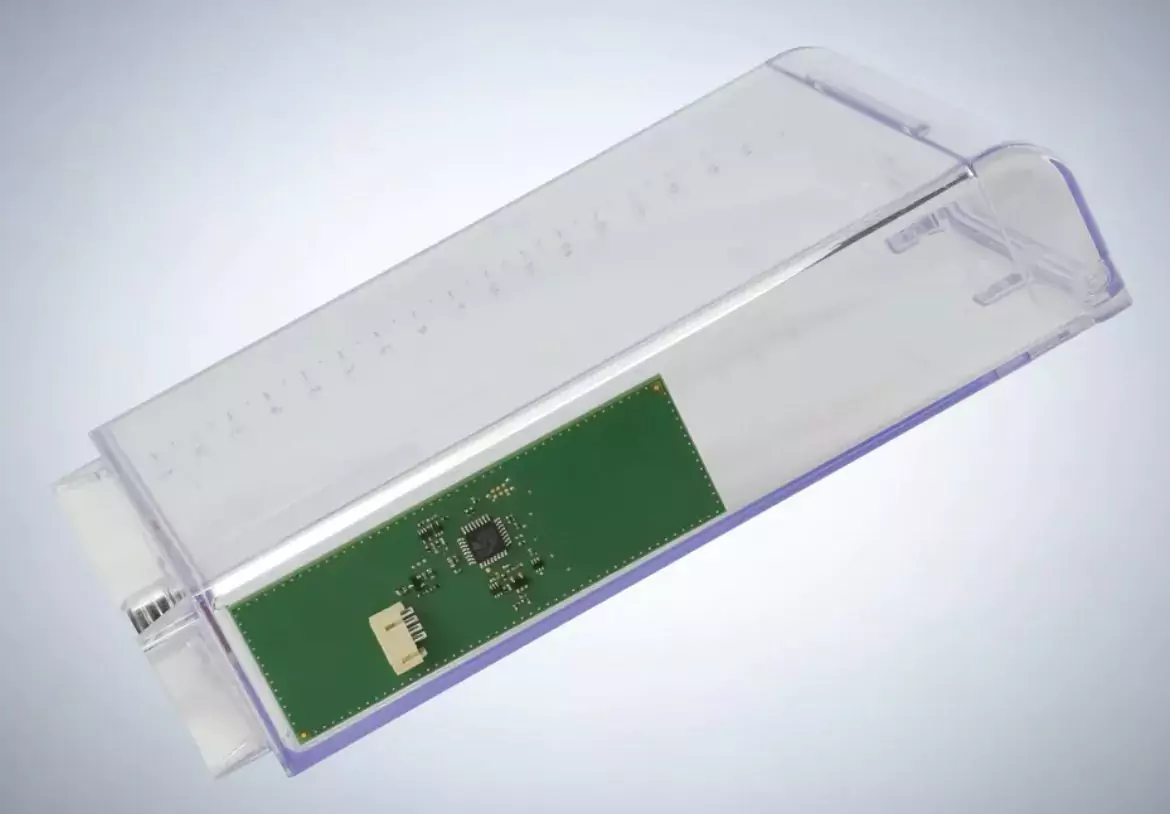

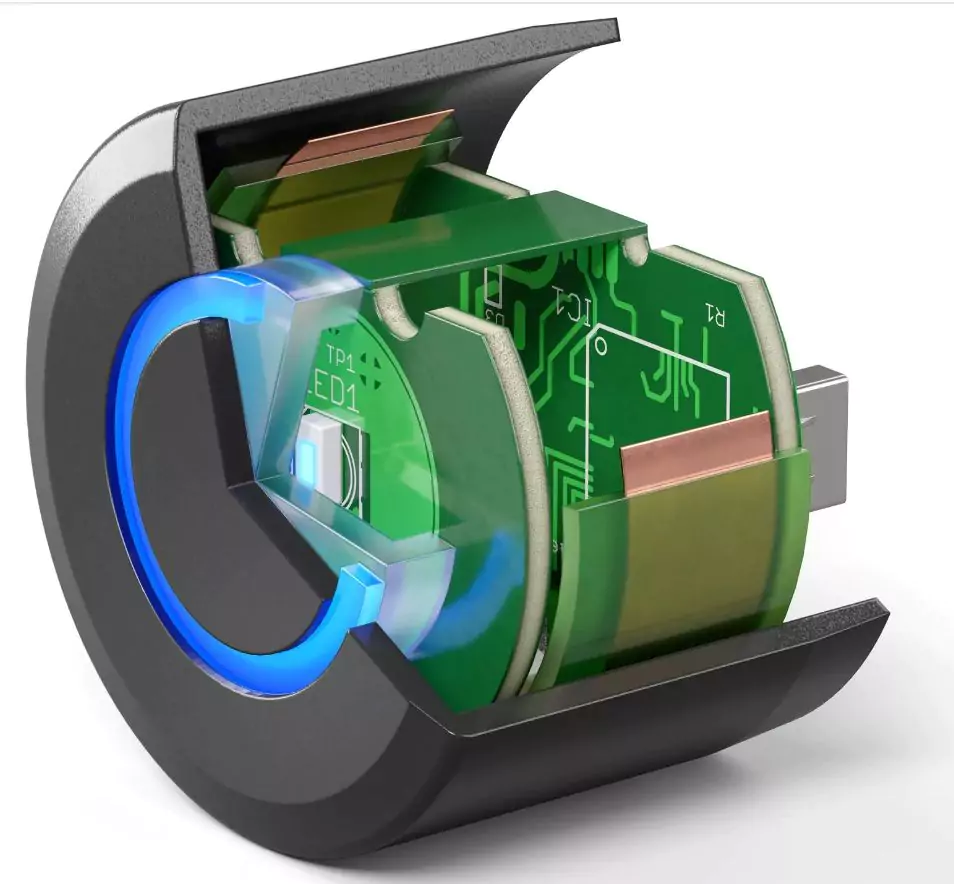

When designing a switching power supply or DC/DC converter and your willing to reach the best possible efficiency of your application, than it's most common to use a planar transformer instead of an equivalent wire wound transformer design. Standex Electronics manufactures planar transformers for these demanding applications and you can rely on decades of experience. When failure is not an option, designers of critical electronic components rely on the engineers of Standex Electronics and the local support of Heynen BV.

Why Planar transformers & Inductors?

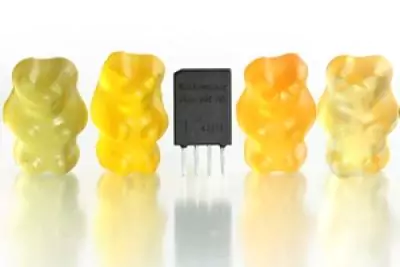

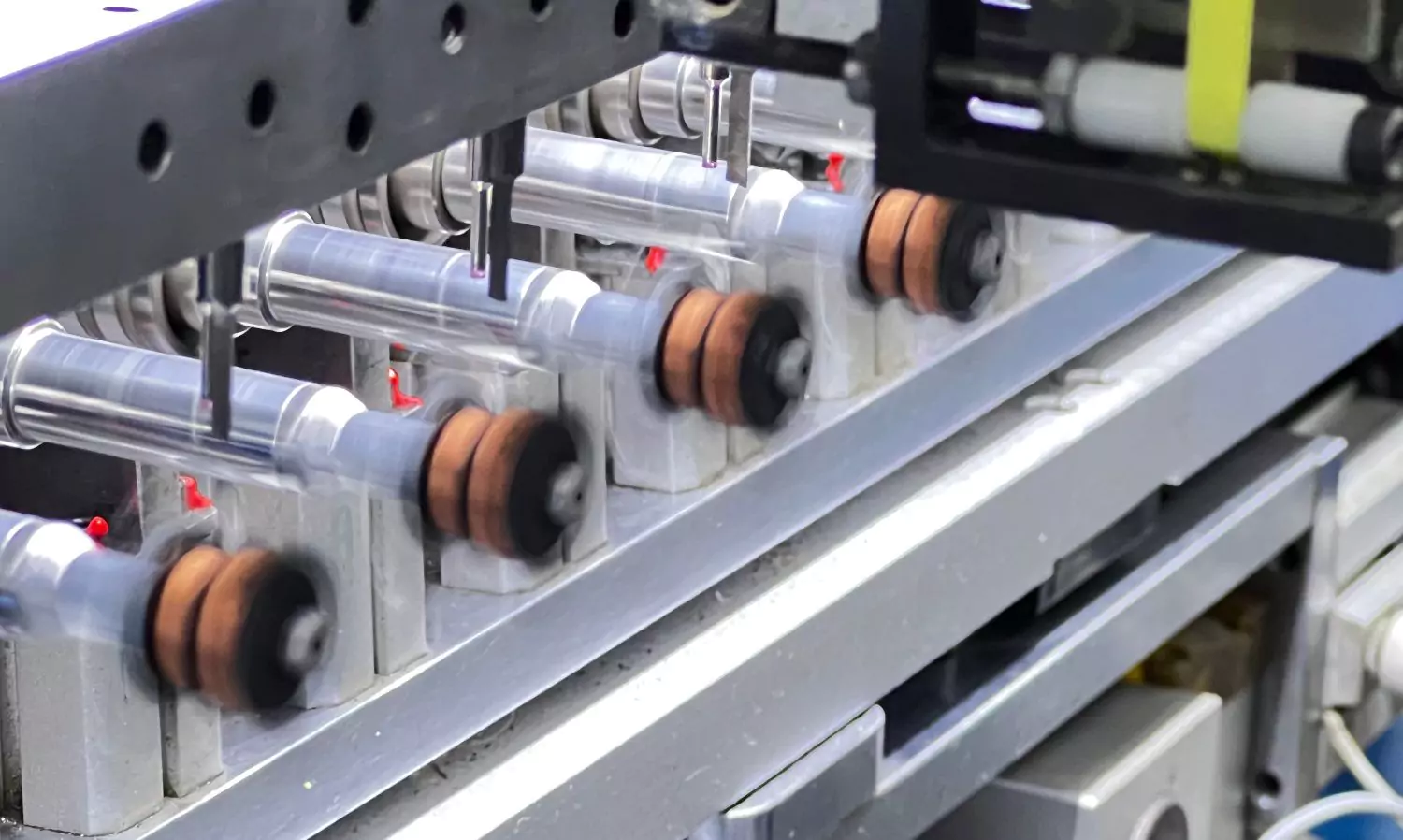

As more and more industries begin to feel the push toward higher efficiency and performance along with miniaturization, the planar transformer continues to emerge as an alternative to wire-wound transformers, making it ideal in certain application “sweet spots”. This solution makes so much sense for today’s applications, and when you combine planar transformers with excellent engineering, you can get a solution that not only saves you space, time, and costs, but suits your needs uniquely and specifically.

Standex Electronics unique advantages

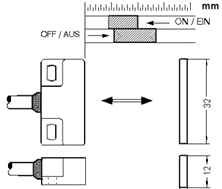

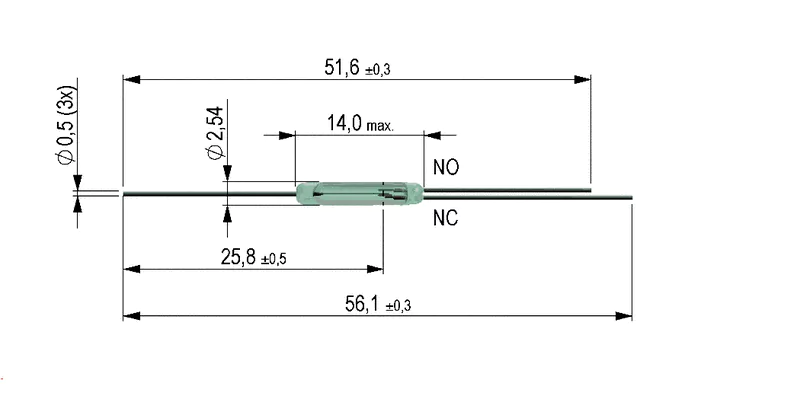

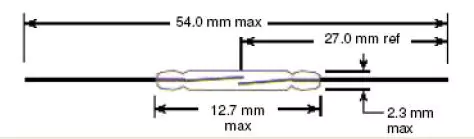

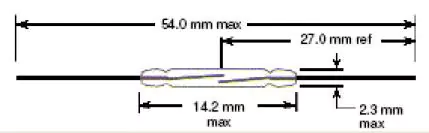

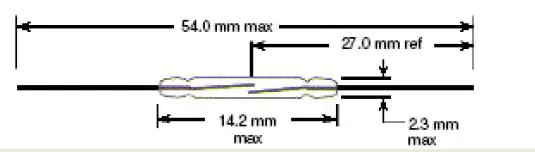

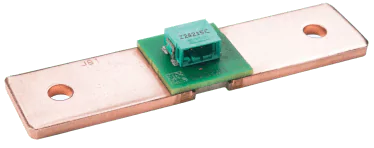

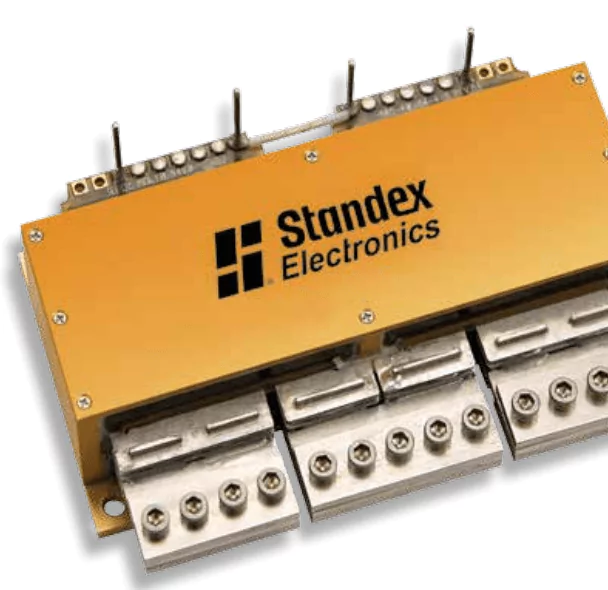

The unique P025 - P1100 product line of planar transformers are equiped with a patented header and terminal design yielding superior thermal management. The planar transformers come in standard sizes and with hundreds of lead frames and PCB windings in stock. They haven flexible, low impedance terminations which have excellent solderability characteristics. Besides, the planar transformers can be quickly customized often without start-up or tooling costs for many power topologies, including soft switching, single or multiple outputs, different switching frequencies, and different input/output voltages as well as multi-winding inductors. All designs meet the required minimum 8mm clearance and creepage distance. Refer to the attached Custom Design Guide Overview.

Applications

Applications include but are not limited to:

- Switching power supplies

- AC-DC resonant designs

- Aerospace & Military (high reliability/repeatability)

- Appliance

- Automotive, Electric and Hybrid Vehicles

- Battery Charging (12V, 24V, 48V, 1-10 KW)

- DC-DC Converters (100W-1200W) in distributed power systems

- Distributed Isolated Power

- Feedback Control

- High Current POL Converters

- High Power LED Lighting, Industrial Power, Welding

- Isolated Inverters

- Isolated (non-regulated) Bus Converter (Vout 9-12V)

- Renewable Energy - Wind & Photovoltaic Power System

- Server – Data Centers (400VDC)

- Telecom Applications (“Sweet Spot” 36-72 Vin 40-250W)

- Welding, Lasers, Test Equipment

Main Advantages

- Better power density and performance

- Compact dimensions

- Custom designs for a wide power range

- Multiple manufacturing facilities incl TS16949 and ITAR

- Engineering-, Testing- and Quality/Lab facilities