Edge-wound Flat Wire Technology

What is Flat Wire technology?

Edge-wound Inductors with flat wire offer several advantages compared to other types of inductors, including a better heat dissipation that allows a higher current density and reduce the dimensions of the component.

With the combination of flat wire with our xgap technology we are able to minimize power losses. Additionally, these chokes perform flat inductance versus current.

These advantages make them ideal for a wide variety of applications, such as PFC, AC, Boost or Buck chokes.

Edge-wound flat wire vs round wire

Flat wire inductors offer several advantages over the traditional round wire winding pattern inductors.

- Thick round wire technology for higher currents brings best efficiency in frequencies up to 20kHz. At higher frequencies the skin effect increases AC resistance, and in this case flat wire is a better choice to limit this effect.

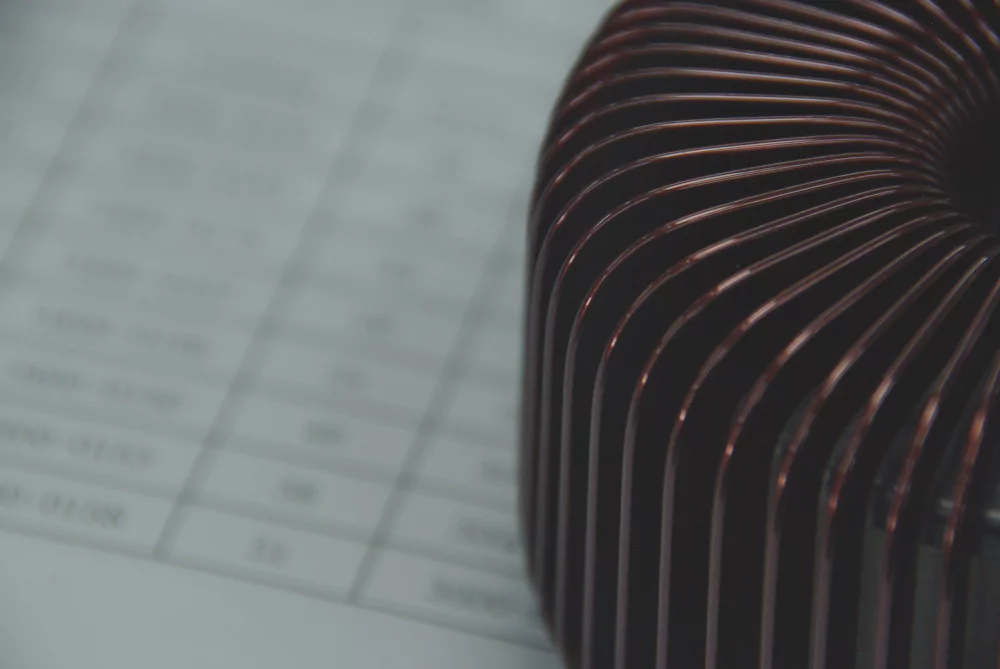

- Flat wire has a larger surface than round wire. This allows to handle higher currents in the same volume. Therefore, edge-wound flat wire inductors are specially indicated for high-current applications.

- Flat wire inductors have excellent heat dissipation due to the ideal distribution of the flat wire in a single layer. This even is improved by using forced air, as in this case the dissipation surface is much larger.

- Another benefit of the distribution of the winding in a single layer is that it keeps the capacitance low, which results in a high self-resonant frequency.

Best cooling performance

The thermal image shows the heat distribution of a toroidal flat wire and a round wire inductor with the same current, inductance value and natural convection.

From the picture it is observed that the temperature rise of the flat wire inductor is 20˚C lower than the round wire inductor.

xgap combined with edge wound flat wire winding

The combination of both technologies has been developed by PRAX as a unique concept. It provides several advantages compared with other solutions.

Benefits of using the multi-gap ferrite cores

- Very low core losses at high frequencies.

- Flat inductance vs current performance.

- Lower cost of the core.

- Ferrite is the cheapest material.

- No aging of the magnetic material.

Benefits of toroidal format and vertical mounting

- Best cooling performance with forced air.

- Easy mounting. Extra pins are included in

- base, no need to screw component.

Main applications

Typically used for PFC inductors, high AC current inductors, Boost and Buck inductors.

- Inductance values between 100-300µH.

- High ripple currents (›30%).

- Frequencies in the range of 50-150kHz.