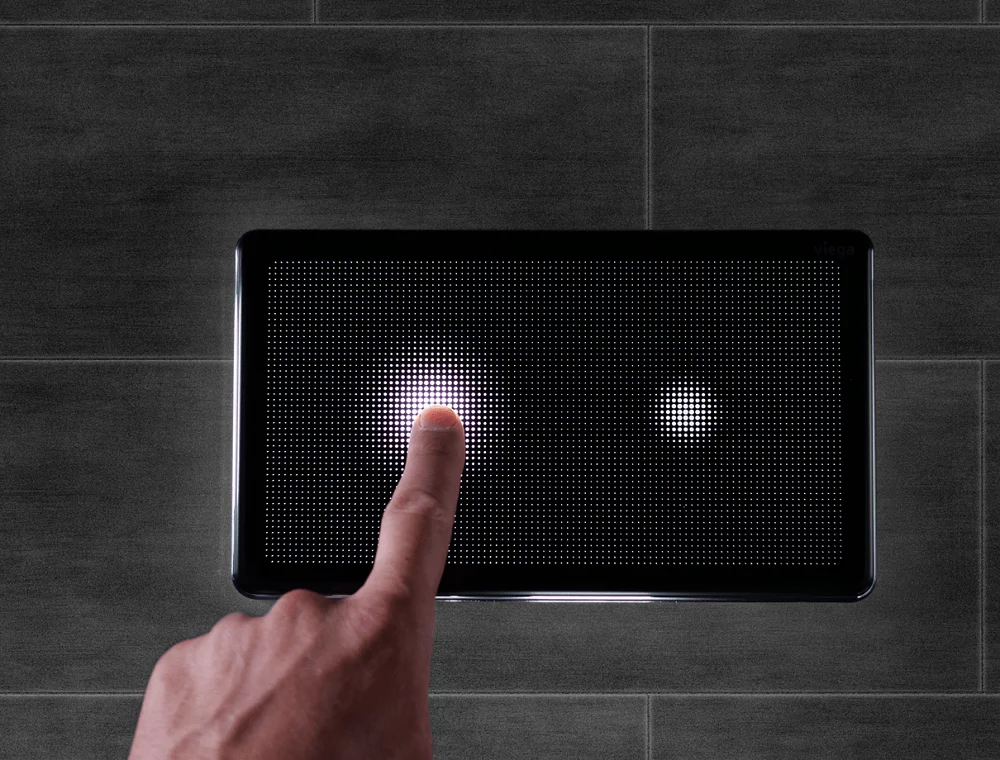

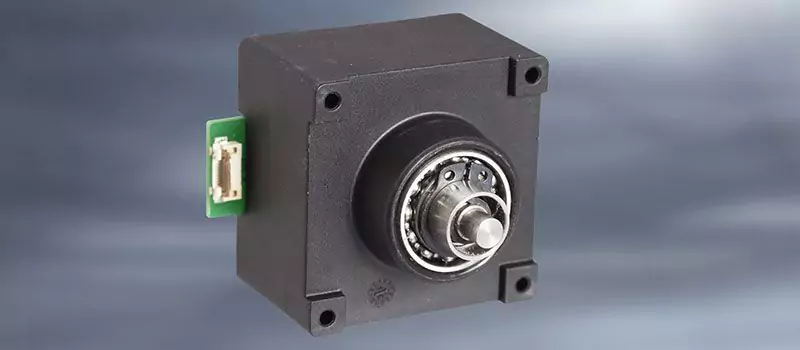

Double rotary encoder with push button function as compact HMI operating solution from EBE

Even in times of touch displays innovative encoder solutions with high-quality HMI-concepts are often still a good choice in terms of user-friendliness, perceived quality and longevity. EBE sensors + motion from Leinfelden-Echterdingen demonstrates this with the double-rotary encoder BGE43 with integrated push-button function, compact design and wear-free magnetic latching mechanism.

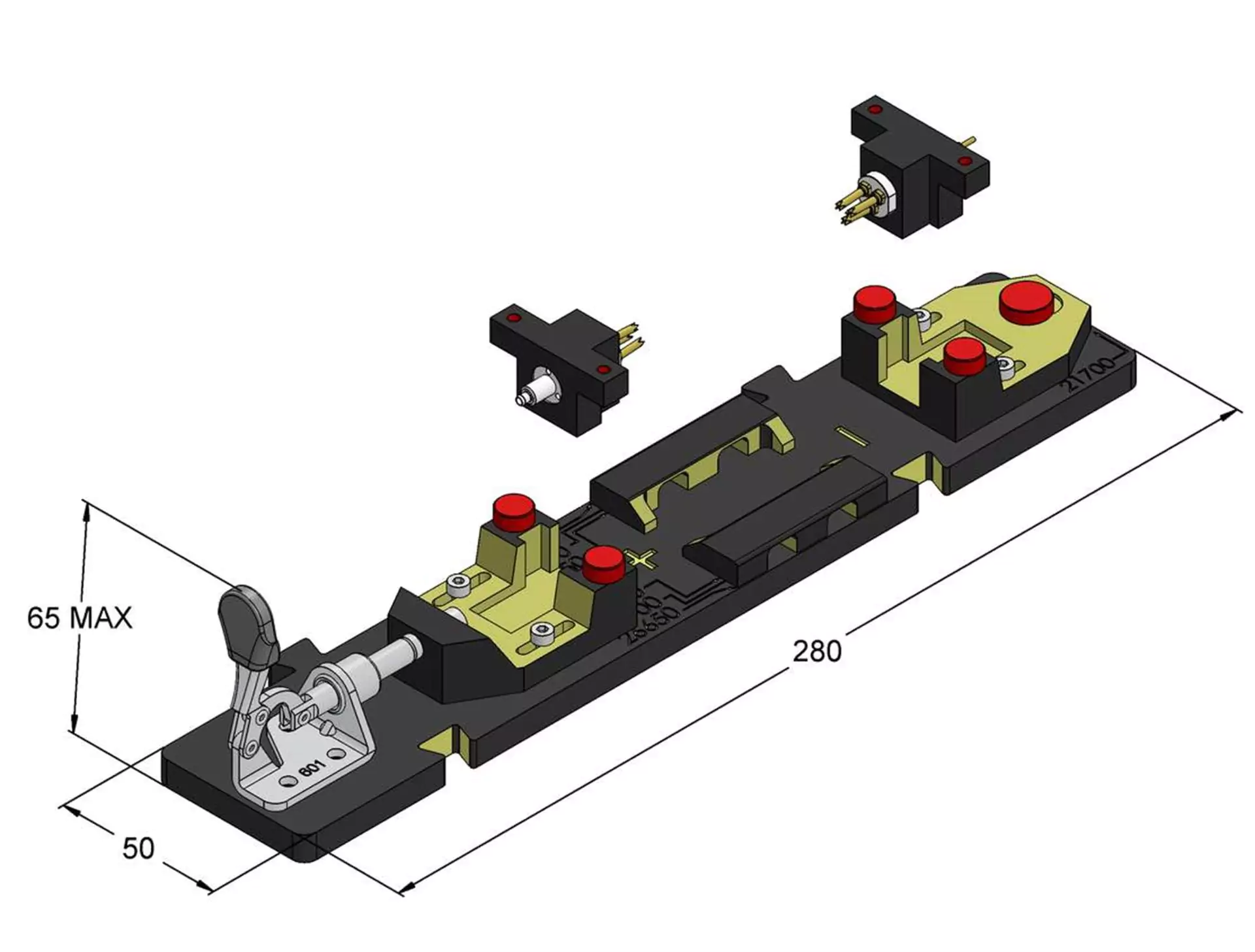

The double-rotary encoder BGE43 developed by EBE integrates two functionally independent encoders including push-button function, all in one axis direction in a compact housing. This combination is ideally suited for applications in which two functionally related parameters need to be adjusted. In this case the push button is often used as the confirm function. Examples are applications for horizontal-vertical-adjustments (azimuth and elevation) or coarse and fine adjustments in one operating concept with different scalings per encoder and subsequent confirmation of the entered values by the integrated push-button function.

This concept allows intuitive, ergonomic operation without the need to alternate from one rotary button to the other. The tactile feedback of the latching mechanism ensures precise operation and allows controlled settings without visual monitoring of a display to be performed.

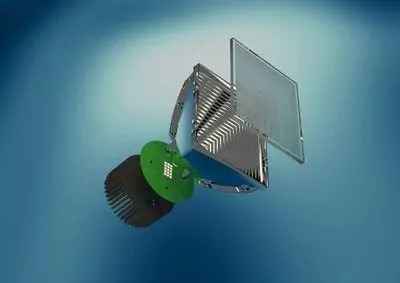

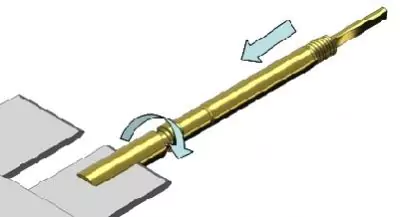

Both rotary encoders are mechanically built-up in sandwich design and can be operated individually via separate inner and outer axes. The inner axis additionally takes over the push-button function which is also designed in Hall sensor technology. In this way two independent track signals and a keying signal can be electrically generated.

The connection of the encoder to the electronics to be controlled is made by a 10-pin ZIF plug connector through which the supply voltage of 3.3 V is applied and the integrated keying function is signalled. Each of the two integrated encoders provides a separate A/B track signal. Beyond that the rotation direction can be recognised.

The ball bearing stainless steel axes ensure high mechanical robustness throughout the entire lifetime as well as steady ease of running and latching force.

The magnetic functional principle uses a permanent magnet to realise the latching and the generation of the A/B track signal simultaneously. The use of a Hall sensor allows a cost-saving overall system. The touchless latching also ensures total wear-free operation with consistently high-quality haptic throughout the entire product lifetime.

The current version of the BGE43 is available with 24 latchings per rotation for each axis. The double rotary encoder is designed for an operating temperature of -20 °C to +70 °C; the housing fulfils protection class IP54. According to the manufacturer EBE, different customer-specific adaptations, e.g. of the latching and rotary force or the number of latchings per rotation, are possible at any time.

The double-rotary encoder BGE43 is suitable for a variety of applications where limited installation space is available and at least two encoders to control the application and high-quality haptic are prerequisite.