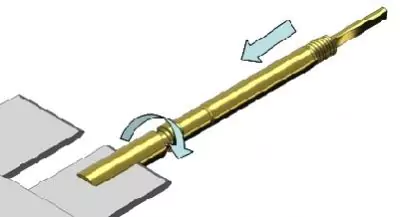

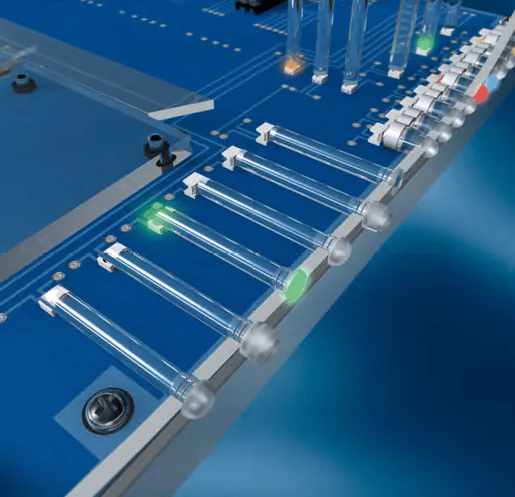

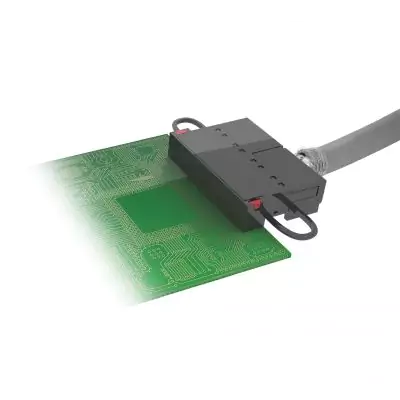

A position test at very limited space by using a probe

A position sensor system is the ideal solution for exact measurement and documentation of pin lengths, hole depths etc. This system can be used like a contact probe even in small centers. An integrated potentiometer allows the exact determination of the position of the DUT.

Increase the product quality

After the assembly of a PCB, wire harness or a complete application, the ultimate question is whether the produced parts meet our quality standards. During a in circuit test or functional test, the correct operation of the assembly can be tested, however tilted components aren't detected and neither if all parts have been automatically placed or not. This can lead to longer quality analysis procedures and rework routines.

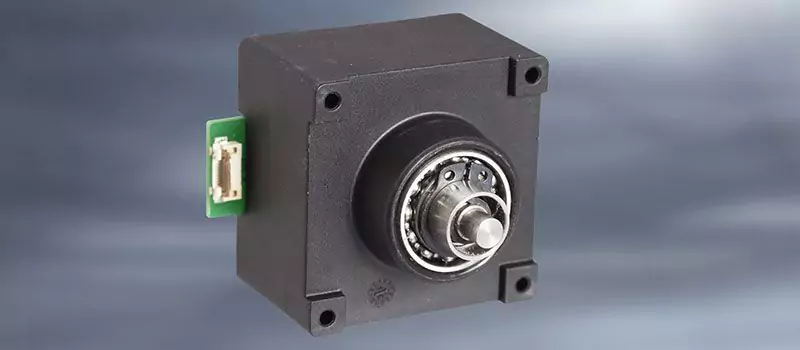

Contact probe solution with integrated potentiometer

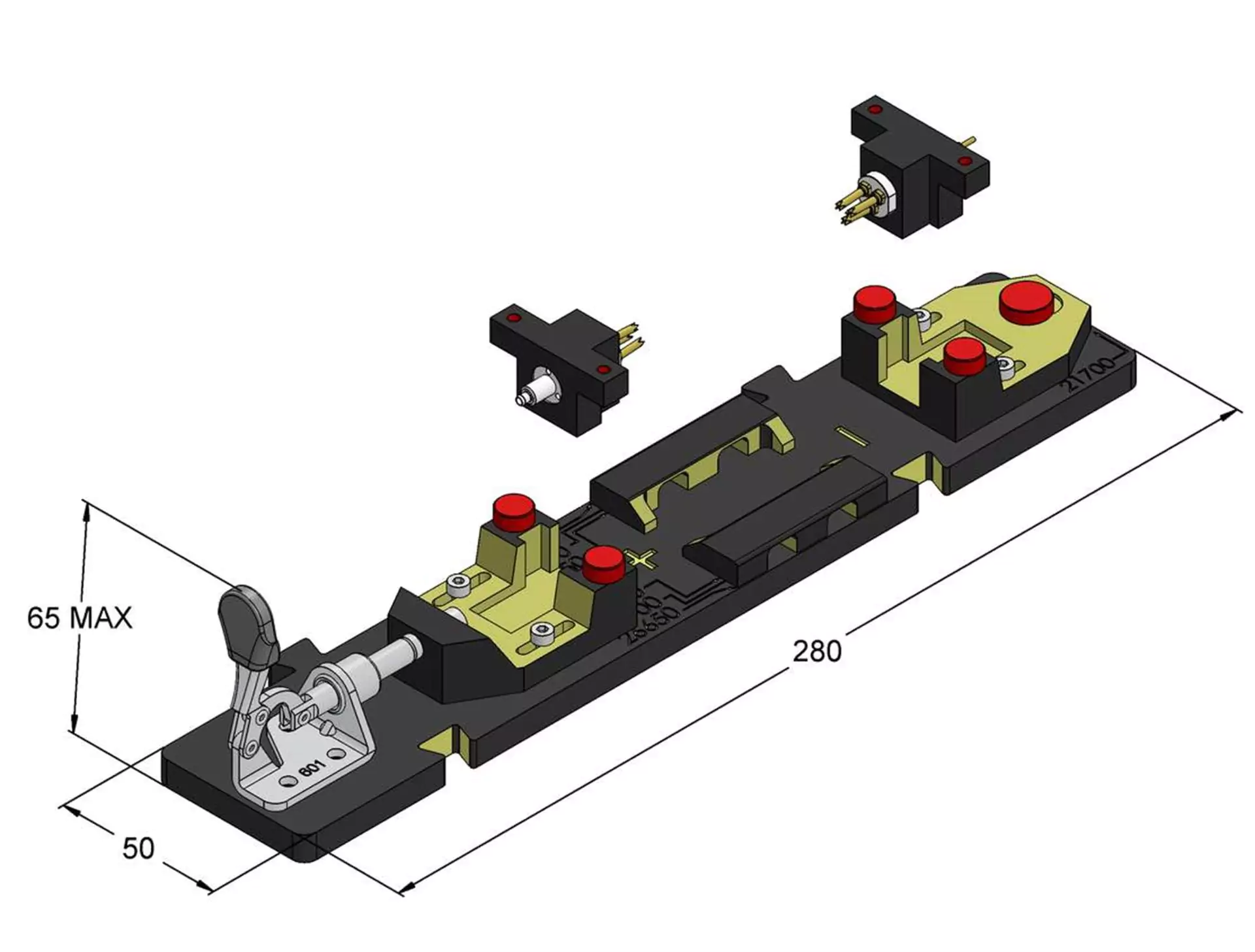

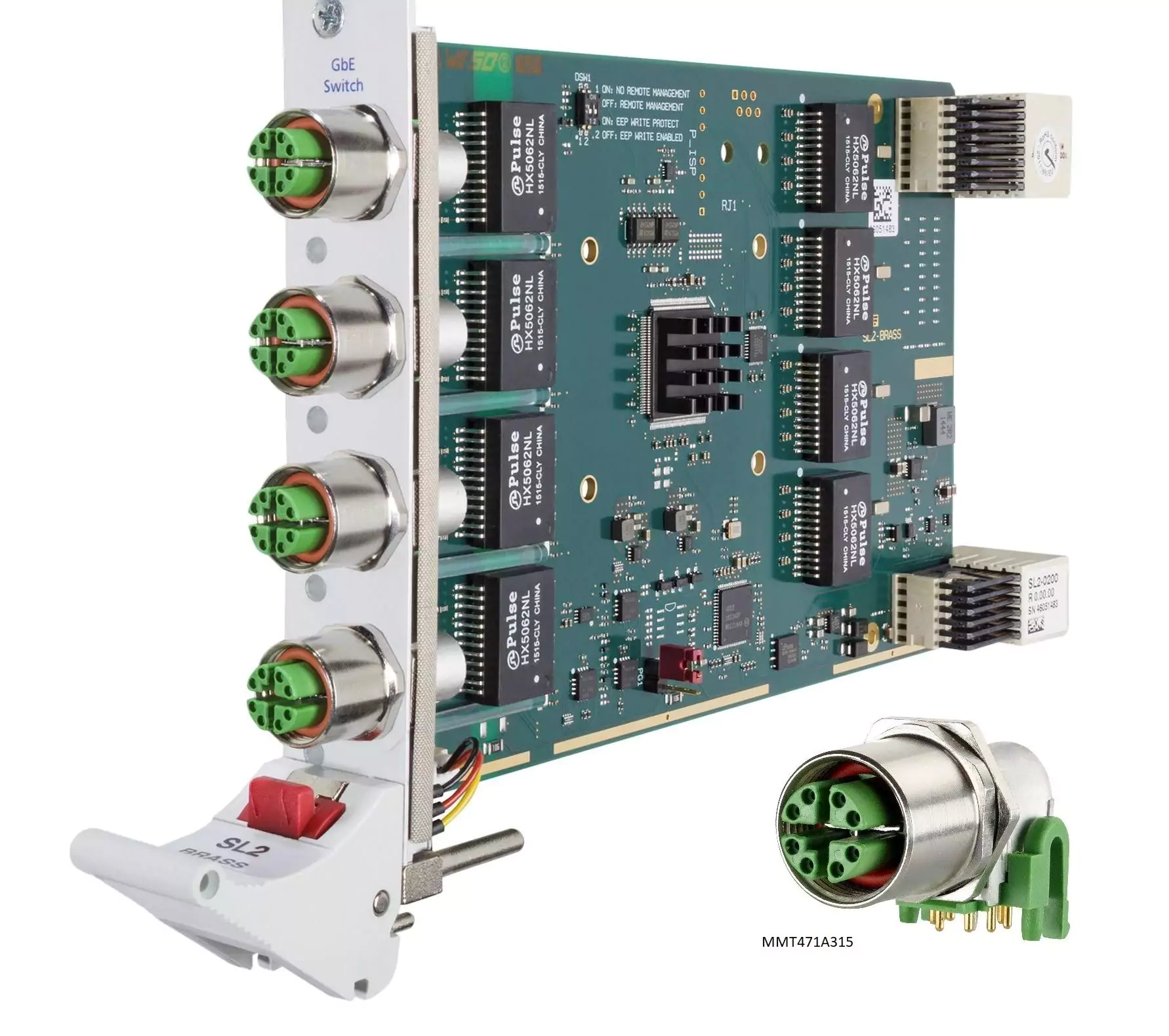

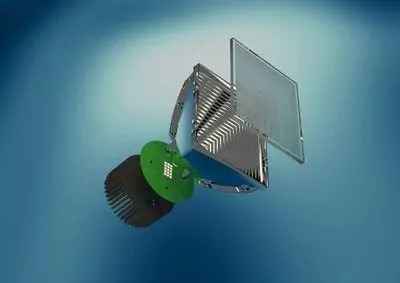

The new Feinmetall position sensor system allows contacting a test item electrically and at the same time measuring its exact position. A position sensor system consists of a contact probe, a receptacle and a position sensor with integrated potentiometer. This system is still so lean that it can be used in fixtures or modules with standard centers like a normal contact probe. The potentiometer function allows determining the exact travel of the probe and thereby the exact position of the test item by analyzing the resulting voltage in the test system. This solution is unique at the market, a patent is pending.

For small centers of only 75 mil

Besides the already introduced position sensor system for 100 mil, now a new slim version for 75 mil has been developed. This version even allows measuring a larger range of up to 6.4 mm travel compared to 5 mm with the 100 mil solution. Also new is a more robust version for applications with 157 mil centers. This version is less sensitive of stronger forces and it can be mounted into airtight fixtures or modules (i.e. leakage rate < 0.5cm³/min at 0.7 bar). Typical applications for position sensor systems are exact measurements of hole depths, pin lengths or component heights as well as examination of injection molded pieces or bending of PCBs. The potentiometric measurement principle results in real quantitative and documentable measuring values. A reference measurement can be made to avoid wrong results caused by tolerances in the module or fixture. The position sensor systems are available with different round tip styles as well as twist proof spade tip styles.

Main Advantages

- Measuring electrically and the position at the same time

- To be used in modules or fixtures with standard centers

- To be used at very limited space

- Centers of only 75 mil